A few nights ago, when my city was blessed with a deluge of rain, I had the misfortune of damaging my car wheel by driving over an open pothole. Cursing my luck, I was musing over the idea that if my wheels were made of sturdier stuff, say stone, then maybe I wouldn’t have been stranded, waiting for a tow truck. Of course, stone wheels had their own set of troubles: slower mobility, lack of spokes, and an overall clumsy design. So how did wheels acquire the form that we’re used to seeing, today?

Humans in the Paleolithic era were aware that round objects were easier to transport compared to irregular shapes because they could be easily transported by rolling. For example, heavy objects such as rocks could be easily moved by placing a round object, such as a fallen tree trunk, underneath it and then rolling the rock over it. However, none of these observations resulted in invention of the wheel, which happened much later. Interestingly, unlike most inventions, wheels were not inspired by the natural world. In fact, the earliest use of the wheel did not involve locomotion at all; they were instead invented to make pottery easier. Pottery involved using a coiling technique, wherein long ropes of clay were pinched together to form a vessel. Instead of walking around the pot and adding layers of clay, it was easier to place the pot on a mat and then rotate it while molding its shape. This procedure inspired the invention of the potter’s wheel. The earliest form of the potter’s wheel was invented in the 5th century BC in the Middle East. The wheel was a platter which was turned slowly while coiling a pot. Around 3500 BC a faster wheel was developed based on the flywheel principle: the rotation of the round, heavy stone released energy which could then be utilized to shape pots more quickly. An added advantage included the ability to create thinner walls and create a variety of shapes. The development of the faster wheel also allowed the process of throwing, which involved placing a lump of clay in the center of the wheel and then molding it, thereby providing an advantage over coiling.

Figure 1: The fidget spinner of the Neolithic age. The statue, from 2000 BC, depicts an Egyptian potter with a pottery wheel.

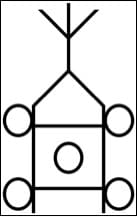

However, extending the principle of a potter’s wheel to create a means of transport took several decades. In fact, archeologists use the development of a wheel and axle as a marker for how advanced a civilization is, as the arrangement allowed for the development of vehicles such as carts and chariots. There are several reasons why this arrangement makes transport easy. Firstly, the wheel reduces the amount of friction encountered, thereby reducing the amount of work involved. For example, moving a bolder would be difficult because of the surface area of the boulder that is in contact with the ground is large. However, if the same boulder is mounted on a wheeled device, the wheels have a much lower surface area, and therefore less friction. Secondly, the wheel and axle combination acts as a force multiplier: if a small amount of force is applied on a large wheel, it can move a large load that is placed on the axle. This is because the mechanical advantage of a wheel and axle system depends on their respective diameters. The wheel which has a larger diameter requires a low amount of force to move. However, since the axle has a smaller diameter, the force transmitted from the wheel gets multiplied, thereby making it easier to transport large objects with a small amount of input. The same is true in a car; when one turns the steering wheel, the force is multiplied by the axle and is used to turn the wheels of the car.

Figure 2: The Bronocice pot (left) and the inscription of a wheel and axle system (right). The image on the pot, which has been dated to the 35th century BC, is the oldest well-dated representation of a four-wheeled vehicle. The vehicle seems to consist of a shaft that is attached to an animal and four wheels that are connected by axles.

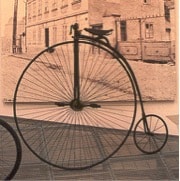

The earliest wheels were made of wooden disks that contained a hole for the axle. These were usually made from horizontal slices of tree trunks. However, these wheels tended to be inferior due to the uneven nature of wood. Driven by a need to use lesser material and build lighter and swifter vehicles, spoked wooden wheels were developed around 2000 BC. These spokes connected the hub of the wheel, which consisted of the axle, to the rim of the wheel. The widely placed spokes were placed radially and helped maintain the shape of the wheel to a large extent. However, the spoked wheels were susceptible to warping if they were subjected to prolonged weight-bearing. Other than the development of iron rims in Celtic chariots around 1000 BC, the design of the spoked wheels remained unchanged until the 1800s. In 1808 George Cayley, an English engineer, invented wire wheels; where the rim of the wheel connected to the hub via wire spokes. This made the spokes stiffer and less susceptible to deformation. Spokes were further improved with the development of tangential spokes, in 1874 by an English inventor, James Starley. Tangential spokes helped create sturdier wheels. Unlike the radial arrangement, where the spokes go straight from the hub to the rim, the tangential placement connected the spokes from the hub to the rim at an angle. This placement allowed the wheel to better withstand the twisting forces during acceleration and braking.

Figure 3: Radial spokes (left) on a bicycle from the 1860s. These bicycles were known as boneshakers because they were exceedingly heavy and were made of a wooden rim that was surrounded by iron tires. These bicycles were then replaced by penny-farthings from the 1870s. The use of tangential spokes made them extremely durable and much lighter.

The final improvement in the wheel design came with the invention of pneumatic tires in 1888 by John Dunlop, a Scottish inventor. These tires were made from an inflated tube of sheet rubber and proved to be superior to the iron tires that were in use at that point. The use of inflated rubber allowed the tires to absorb shocks better and made them more resilient. The same design was later used for the production of car wheels in 1900 and the design has remained virtually unchanged since then.

However, that brings us back to the original question are we doomed to a future of rubber tires which are susceptible to becoming flat, or bursting due to an open pothole on a rainy night? It turns out that the French tire company Michelin has developed the Tweel- a wheel and tire combination that does not use a compressed air bladder and instead uses a rubber tread that is attached to the hub with flexible spokes. Unfortunately, these tires cannot be used at higher speeds due to increased vibration of their components. The journey of the wheel from an innocuous pottery tool to it’s current omnipresent form is a perfect example of the onward march of mankind. What is especially exciting is that although the wheel has been modified for millennia, there is still so much scope for improving what is essentially a perfect design. One can only imagine what the future holds in store.

Figure 4: Tweels- tires of the future? The flexible spokes absorb the shock fulfilling the role of air pressure in pneumatic tires. The outer band deform temporarily with the spokes bend and then they spring back into shape.

This article was originally published with the help of the editors at Club SciWri.